The core program of pump building in Zimbabwe has grown with 432 Elephant Pumps installed in 2012 compared to 367 in 2011. This is now a massive program with the Elephant Pumps, managed by The Africa Trust, providing clean water for over 10% of the entire population of Zimbabwe. In addition to the core staff, it has been possible to provide contract work to over 40 other individuals during the course of the year.

The Elephant Pump was awarded the St Andrews Medal for the Environment in 2005, competing against 250 other applicants. Prince Charles, a patron for the St Andrews Medal, gave a personal recommendation towards this option of water extraction:

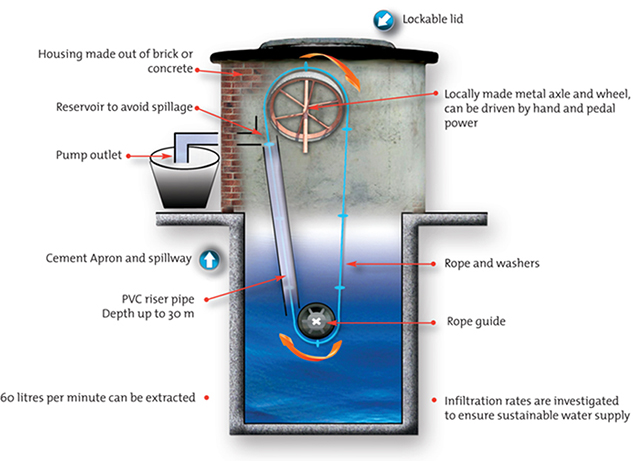

“Each project has had a direct and positive impact on people’s lives. While it is perhaps invidious to highlight just one of them, I believe a good example is the success of The Elephant Pump project. Based on a 2000-year-old Chinese technique for lifting water, The Elephant Pump is inexpensive, simple to make and repair and made from locally available materials which give users a greater sense of ownership. When more than a billion people live without access to clean drinking water in the world today, it is hard to imagine a better cause than this”.

Diagram of The Elephant Pump

Ian Thorpe then became the first person to win The St Andrews Medal for the Environment on two separate occasions when his design for the Elephant Toilet was awarded in 2008. Since winning the medal, this toilet has been introduced throughout northern and central Malawi.

Pump Minders – Key to Sustainability

It has been seen that the pumps which have been well maintained over the years are at sites where at least one key person has been trained on how to maintain the pump. Instead of simply providing general training for the whole community, The Africa Trust has recognised that it is vital to train at least two people who are likely to remain in the community. Many young men leave the rural areas in search of work. Older women are often the best people to train, as they are less likely to move away.

Once identified, 2-3 pump minders per pump receive initial training when the pump is installed with further training after 3 months, 6 months and one year. By this time, it is expected that the pump minders will be able to do all minor repairs with informal payment in kind (often in the form or food) from the others who use the pump. Spare parts for the pumps (such as washers and rope) are made from waste products and the pumps contribute to increased agricultural production, so this approach to maintenance is sustainable.

Pump minders collect a low level of community contributions once the pump is productive to pay their wages and a small part returns to The Africa Trust. This helps pay back the capital cost over five years. Millions of people in over seven thousand communities use Elephant Pumps.

Trackbacks/Pingbacks